When selecting retail fixtures, you may not give much thought to the processes used to apply color and finish, but they do make a difference in the long-term appearance of your investment, and your brand image.

In this post, Larry Johnson, Engineering Manager at L.A. Darling, will review the powder coating process and share insights on why it’s L.A. Darling’s choice for the products they manufacture, and why the right finish matters to your retail operation.

Raw metals need protection for extended life

Most of the fixtures L.A. Darling produces – as well as cash wraps and display cases – are constructed of steel. The base material is plain mild steel, while in other cases, aluminum might be used.

Exposure of untreated metal to air and moisture ultimately leads to oxidation and a decreased product lifespan. To prevent or slow deterioration from rust or corrosion, fixtures need some type of protective coating.

“Stainless steel has its own hard finish, so we typically don’t paint stainless steel,” says Johnson, though it is something that can be done upon customer request.

Typically all vertical and interior surfaces receive a powder coat. The most popular industrial methods for protecting metal fixtures are liquid paint and powder coating.

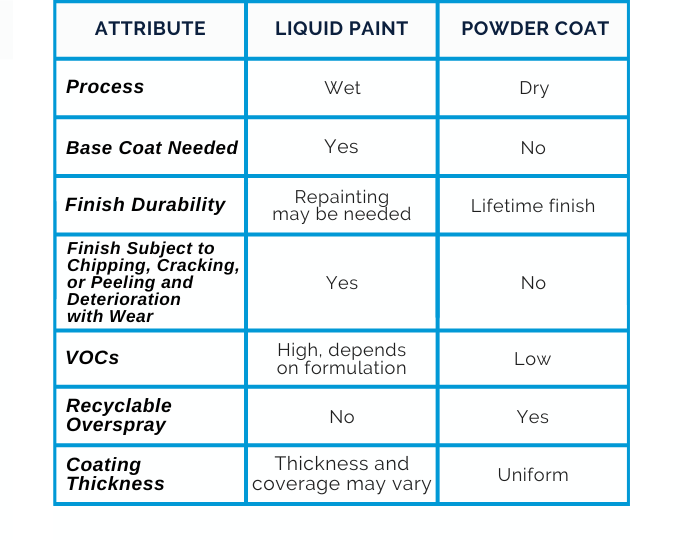

For a quick overview, here’s a side-by-side comparison of the two methods. We’ll explain more about the advantages of powder coating in the following section.

Powder coating offers advantages over wet paint

Powder coating delivers a superior performance compared to a liquid paint coating for retail operations that depend on long-wearing fixtures. It also provides the best quality finish.

That’s why L.A. Darling chooses to powder coat all fixtures as well as vertical and interior surfaces of cash wraps, cabinets, and display cases. Here are some of the top advantages powder coating offers.

Durability to withstand impact damage

In the coating process, fine particles of powder cover all areas of the part in an even and uniform layer that is baked at high heat and bonded to the surface.

The hard finish produced resists cracking, chipping, peeling, and scratching to offer durability beyond what can be accomplished with liquid paint. Dings from shopping carts, hand trucks, and the like are no threat to the surface integrity.

Corrosion resistance

Powder coated steel resists corrosion because the powder adheres even to hidden interior areas, effectively “sealing” the metal. The coating also protects against UV damage and abrasion so metal fixtures can serve in both indoor and outdoor applications.

Smooth, even finish that doesn’t need repainting

Paint forms a coating that sits on top of the base metal. It can also run or drip during application, resulting in irregularities and an uneven finish. Paint layers can vary in thickness, producing uneven coverage and inconsistent adherence to the undercoat.

These layers are subject to damage that can cause it to crack, chip, bubble, or peel. Any imperfections in the paint’s adherence to the base material have the potential for trouble. Johnson talks about having seen this problem over the years.

Lower toxicity

Liquid paints typically release volatile organic compounds to a greater or lesser extent based on the paint formulation. Powder coating, because it doesn’t involve a liquid that needs to evaporate, releases almost no VOCs.

As sustainability requirements evolve, reduced toxicity could be reason enough to opt for powder coated fixtures.

Reduced waste and improved process sustainability

Powder recycles. That means the over-sprayed powder that doesn’t stick to the metal parts as they move through the coating chamber can be recovered and reused.

L.A. Darling captures and recycles all powder, so there’s no waste, says Johnson. Again, reuse of materials is a significant part of L.A. Darling’s overall sustainability practices.

Fewer steps and greater efficiency for fast turnaround

Unlike painting, powder coating is applied directly to the base material in a single step without the need for a base coat of primer.

Fewer steps, less material, and a more efficient process make powder coating compatible with automated production and that translates into better turnaround time for customer orders.

The automated powder coating process at L.A. Darling delivers consistent quality

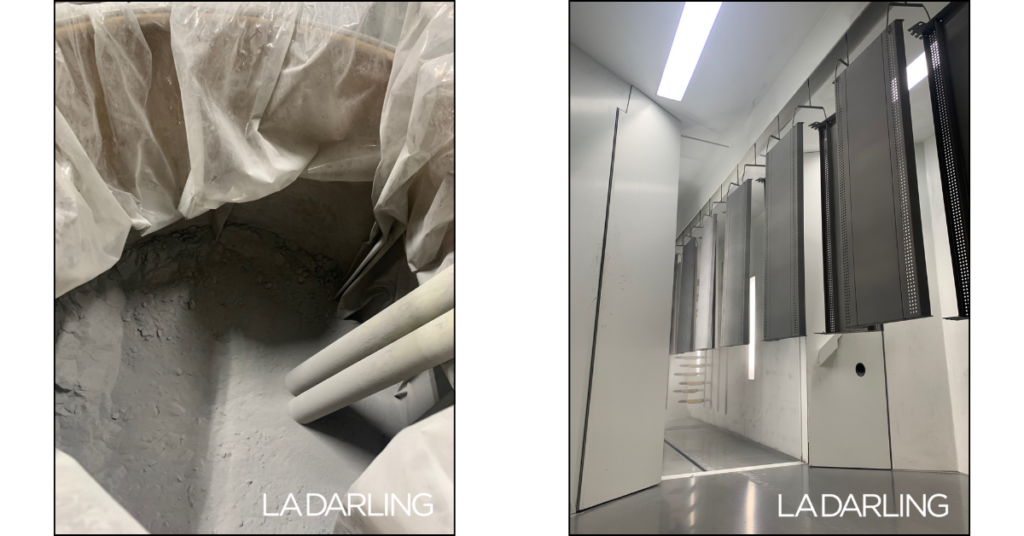

Now that we’ve considered some of the attributes of powder coating that give it an edge over wet paint, let’s take a look at the automated powder coating process used by L.A. Darling.

Not only is powder coating the more modern finishing choice, it’s also compatible with automated manufacturing processes.

Johnson talks about the overall process that L.A. Darling uses:

Powder coating in general produces an even and uniform finish. Automating the process offers greater efficiencies and ensures customers of finish consistency as well as efficient production speed for faster turnaround time.

From start to finish, the coating process takes about two hours to travel through one of L.A. Darling’s mile-long production lines. Unfinished metal goes in, and in a single pass, exits the process with a hard, durable finished surface with the color or clear coating of choice following these steps:

1. Welding and manufacturing of the fixtures is handled upfront. Many items require assembly with pop rivets or screws. Coating before assembly ensures the best finish throughout; L.A. Darling also can accelerate the process and reduce costs by assembling cabinets before coating.

2. Bare metal parts entering the line go through a water-based cleaner. Following this, they go through an oven to be dried and heated in preparation for the powder application.

3. Powder spray guns create a cloud of powder inside the chamber that surrounds each piece. The part and the powder are given opposite electrical charges so the powder sticks to all areas, ensuring smooth and complete coverage even for irregular and complex shapes.

The powder itself is a mixture of pigments and other ingredients, finely ground to the texture of talcum powder.

4. High heat ovens melt the coating so it hardens onto the part and forms a solid coating before it cools and exits the line on the way to the next assembly step.

Versatile powder coating options and trends add customization possibilities

Powder coating is increasing in popularity as a durable solution for protecting metal, from under-the-hood auto components to industrial applications to consumer appliances.

Powder coated mixers, refrigerators, washers, and dryers can be counted on to add a pop of color that may also display a specialty matte or other finish. Outdoor furniture often displays a rugged textured coating that blends style and robust protection.

The same color and style trends shaping consumer appliance choices are available for custom retail fixtures to incorporate a brand’s signature color and style characteristics.

- Matte finishes. The current trend is toward matte, dull finishes—flat black, black chrome, blacks, greys, and even white—and away from “the high gloss that everybody used to like,” says Johnson.

- Textured finishes. Fingerprints detract from the look of a surface. One of the best solutions to this challenge is textured powder coating, says Johnson, “there are some heavy textures, hammer tones, and also some just light, fine textures – ones that completely resist any kind of fingerprinting.”

- Clear coats. One of the new trends Johnson especially likes is “just a clear powder coat that goes over the [bare] metal…you see all the weld marks, you see all the burn spots where there’s been spot welds or sometimes even that rust look, so it’s a very industrial look.”

- Colors. Powder coating is extremely versatile. It can be mixed to produce any color that a customer wants, following either the Pantone PMS color system or the industrial RAL color system. With standard color systems, matching is a snap, even for components added on later.

Powder coated fixtures deliver long life and top performance

Retail fixtures are subjected to hard use, day in and day out, so a finish that’s durable and provides lasting performance is necessary to protect your investment. That’s where powder coat ticks all the boxes as the best finish for fixtures.

Quality, durability, and compatibility with modern automation technology are also reasons why L.A. Darling chooses to powder coat all interior and vertical surfaces of cash wraps and cabinets, as well as gondolas and other fixture elements.

Whether you’re matching an existing installation or creating something entirely new, L.A. Darling has construction, finish, and color options that will meet your goals and customization needs.

L.A. Darling offers collaborative solutions to a wide range of retail fixture challenges. Find out more about what it’s like to work with our problem solving team.